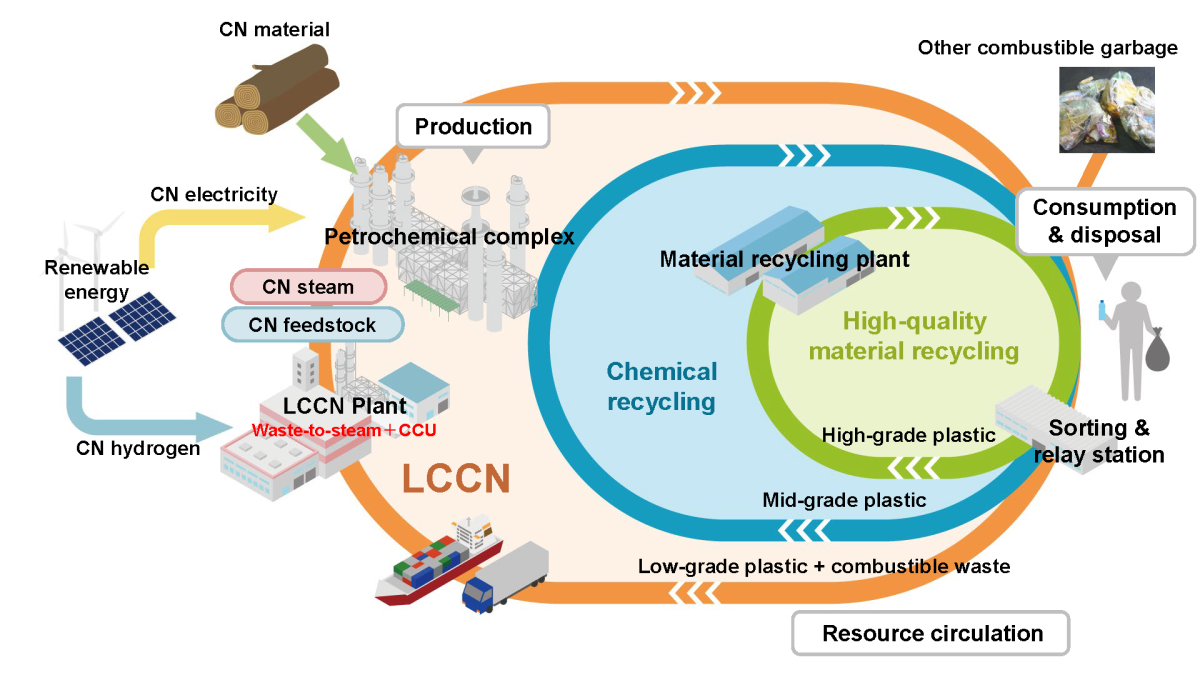

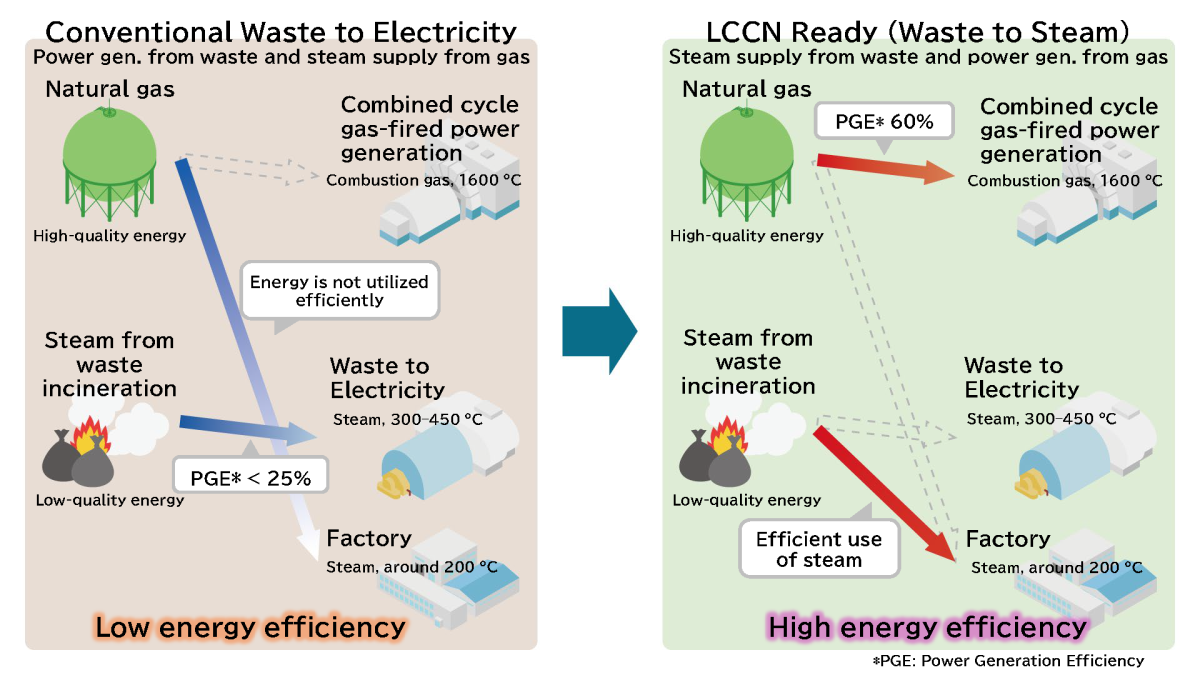

Preparations are underway for the social implementation of a new system, Life Cycle Carbon Neutral (LCCN), which aims to achieve carbon neutrality throughout the lifecycle of materials from production to disposal. In this system, we use heat produced by waste incineration as energy in chemical plants, paper mills, and other industrial facilities, and use CO2 released by incineration as a raw material for producing plastics.

Why is it necessary now to implement the LCCN system, including utilizing heat and CO2 produced by waste incineration, in addition to recycling? We asked Dr. Fujii, who is working to accelerate the social implementation of LCCN systems domestically and internationally.

Dr. of Eng. from the Graduate School of Engineering, the University of Tokyo(UTokyo).

After working as an assistant professor at UTokyo, he joined the National Institute for Environmental Studies as a researcher in 2003 and was promoted to his current position in 2017. He is also a visiting professor at the Nagoya University Graduate School of Environmental Studies and UTokyo Graduate School of Frontier Sciences, and is the Chair of the Council for Advance Resource Circulation and Digitalization.